Four tips in the construction process of self drilling anchor bolt

As an efficient anchoring method, self drilling anchor bolt is used in complicated, loose and broken geological condition. It’s also widely applied to pre-support project, radial support project, slope stabilization, foundation support project, roadway support project, soil nail wall, back pull anchor rod retaining wall and other rock supporting work. There are 4 tips in the construction process of self drilling anchor bolt:

Before installation, the constructor should inspect whether the hollow anchor bar and the water hole are unblocked. If blocked, clear up in time.

After the anchor bolt is drilled into the designed depth, the hole should be washed by water or air till the water or air is returning from the bottom. Only at this moment, should the plate and nut be installed in time to fix the hollow anchor bar temporarily.

The grouting material had better be pure cement paste or cement mortar in which the proportion of the cement and sand is 1:1 and the proportion of the cement is 0.4~0.5. When adopting the cement mortar, the diameter of the sand should not be bigger than 1.0mm.

The grouting material should be injected through the hollow anchor bar and when the intensity of the cement mortar reached 5.0 Mpa, the nut can be tighten.

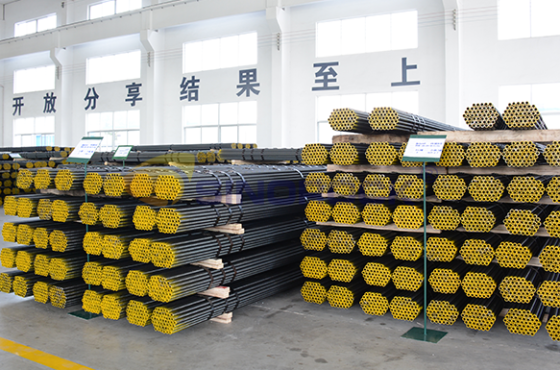

Sinorock has been providing the finest self drilling anchor bolt system products and services in the geotechnical anchor engineering.We manufacture and galvanize self drilling anchor bolt system with variety diameters.Sinorock also has a complete team offering the service from site construction and anchor selection to technical adjustment. Above all it can provide the customer the most professional and reasonable scheme.It not only provides standard products, but also the special products upon the customer requirements.